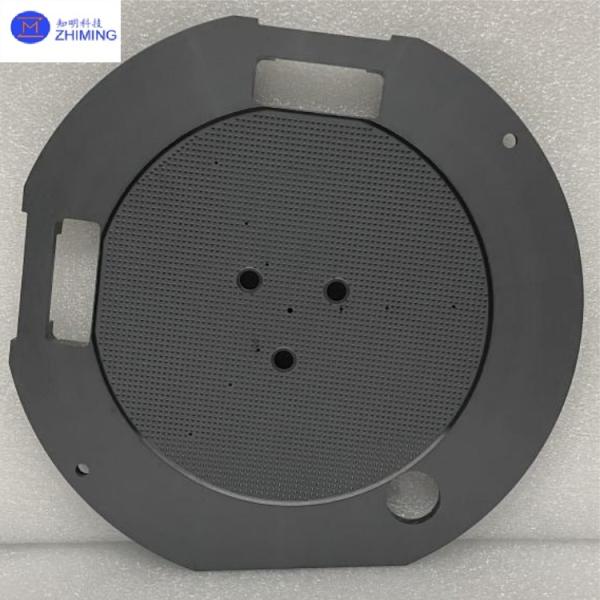

Customized SiC Ceramic Suction Cups for Lithography

Applications

As a core component of the wafer stage in lithography machines,

the silicon carbide (SiC) SiC Ceramic Suction Cups provides an

extremely stable and thermally insensitive reference platform

for wafers, owing to its ultra-high flatness, high stiffness, and

low coefficient of thermal expansion. This is critical for achieving nanometer-level motion accuracy

and repeatable positioning. Its internal precision micro-channel structure enables

uniform and stable adsorption of the wafer via vacuum negative

pressure, avoiding damage or micro-deformation caused by

traditional mechanical clamping. Simultaneously, the excellent thermal conductivity of silicon

carbide facilitates rapid equilibration of the wafer surface

temperature, reducing thermal gradient-induced deformation,

thereby ensuring line width uniformity and overlay accuracy. Furthermore, the inherent properties of the SiC Ceramic Suction

Cups—being dust-free, wear-resistant, and chemically

inert—allow it to meet the stringent requirements of Class 100

and above cleanroom environments, significantly minimizing

the risk of wafer defects caused by particle contamination

SiC Ceramic Suction Cups Data

Parameter Category | Parameter Name | Typical Value/Range |

Physical Properties | Density | 3.1 g/cm³ |

Elastic Modulus | 410 GPa |

Bending Strength | 500 MPa |

Thermal Properties | Coefficient of Thermal Expansion | 4.6×10⁻⁶/K |

Thermal Conductivity | 170 W/m·K |

Maximum Operating Temperature | >1600°C |

Surface Properties | Flatness | ≤ 0.5 μm |

Surface Roughness (Ra) | < 0.1 μm |

Adsorption-Related | Pore Size (Porous Type) | 5 - 50 μm |

Electrical Properties | Resistivity | 10^6 Ω·cm |

SiC Ceramic Suction Cups Characteristic

1. Ultra-High Precision & Mirror Polishing:

- SiC ceramic suction cups achieve a flatness within 0.3–0.5 μm

through precision grinding and polishing, with surfaces capable of

mirror-level polishing (surface roughness Ra < 0.1 μm) .

2. Ultra-Lightweight Design:

- Through lightweight structural designs (e.g., hollow or honeycomb

configurations), SiC ceramic suction cups significantly reduce

mass while maintaining high stiffness .

3. Exceptional Wear Resistance & High Stiffness:

- Silicon carbide ceramic boasts extreme hardness (Mohs hardness

9.5, second only to diamond) and outstanding wear resistance,

ensuring long service life. Coupled with high stiffness (elastic modulus up to 410 GPa),

it effectively resists deformation, maintaining stability under

high-speed motion and heavy loads.

4. Low Thermal Expansion:

- The SiC ceramic suction cups exhibits a low coefficient of

thermal expansion (≈4.5–4.7×10⁻⁶/K), making it highly insensitive

to temperature fluctuations and resistant to thermal deformation.

Application of SiC Ceramic Suction Cups in Lithography Machines

1.Ultra-High Precision Wafer Carrying and Positioning: Leveraging its exceptional flatness (achieving 0.3–0.5 μm), high

stiffness, and low coefficient of thermal expansion, the SiC

ceramic suction cups provides an extremely stable, flat, and

thermally resilient reference platform for the wafer.

2. Vacuum Adsorption and Stable Clamping: Through its precise micro-channel structure, the SiC ceramic

suction cup applies vacuum pressure to uniformly and securely

adsorb the wafer, preventing any displacement or vibration during

high-speed motion.

3. Thermal Management Stability: The high thermal conductivity of silicon carbide facilitates

rapid equilibration of the wafer surface temperature, reducing

thermal gradient-induced expansion differences, thereby

effectively suppressing wafer thermal distortion.

4. Meeting Stringent Cleanroom Requirements: The SiC ceramic suction cups generates no particulate debris, is

wear-resistant, has low outgassing, and resists chemical

corrosion, enabling it to meet the operational demands of

lithography machines in Class 100 or higher cleanroom

environments.

Lithography machine worktable

ZMSH SiC Ceramic Custom Parts

Please feel free to contact us if you have any customization

requirements.

SiC Ceramic Suction Cups FAQ

Q1: What are silicon carbide (SiC) ceramic suction cups primarily

used for?

A1: They are critical for high-precision handling and

transport of wafers and sensitive substrates in semiconductor

manufacturing, photovoltaics, and precision optics, ensuring

contamination-free and stable adsorption under extreme conditions

(e.g., high temperature, high vacuum).

Q2: Why choose silicon carbide over other materials for suction

cups?

A2: Silicon carbide offers exceptional hardness (Mohs 9.5),

high thermal stability (resists temperatures >1600°C), low

thermal expansion, and superior chemical inertness, making it

ideal for applications demanding ultra-cleanliness, wear

resistance, and dimensional stability under thermal stress.

Tags: #SiC Ceramic Suction Cups, #Customized, #Lithography Applications